An integrated system for removal of toxic heavy metals

ICET Inc. is bringing to market a unique technology that has been developed over the past five years. This technology allows carbon materials to remove trace heavy metal species from waste waters and drinking water. These materials show similar or higher capacities for heavy metals compared to ion exchange resins and possess DISTINCT economic and environmental advantages. Using its unique patented antimicrobial technology, ICET can also provide materials that prevent the biofouling of the carbon or other media. Such antimicrobial materials can also be used with reverse osmosis, water treatment and filtration applications.

Heavy Metals Removal System that handles 1-3 GPM

Applications include: Hospitals and Medical Laboratories, Analytical Laboratories, Medical Waste Incinerators, Coal-Fired Utility Scrubber Water, Chlor-Alkali Industry, Mining Operations, Electroplating Industrial Waste, Dental Clinics, Drinking Water Treatment, RO Operations.

ICET, In collaboration with a large manufacturer of engineered systems Kinetico Inc., is well positioned to offer compelte contractual services for low and high volume operations. In a recent end-of-pipe pilot demonstration, complex waste water from two major hospital associated clinical research laboratories in the CIty of Boston and containing lead (60-1000 ppb), copper (300-2000 ppb), and mercury (2-300 ppb) was successfully treated with carbon based sorbents showing and effluent concentration of less than 1 ppb.

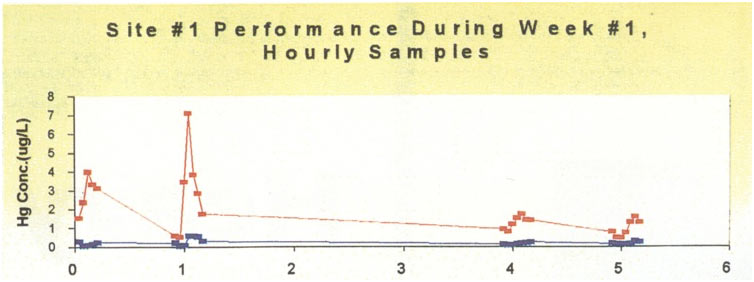

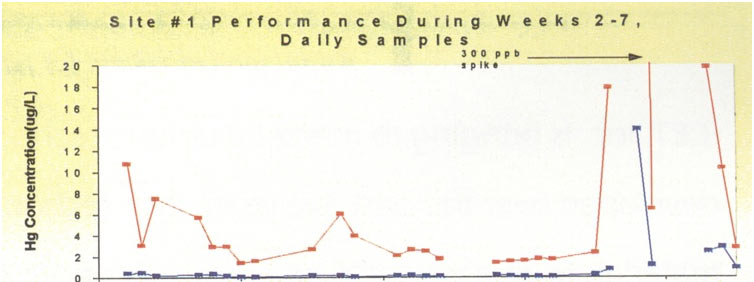

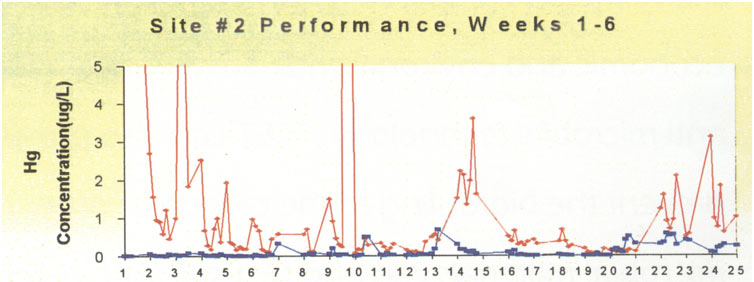

A flow rate of 1 gallon/ minute (5 bed volumes) was maintained for 8 hours/ day for seven weeks. The study at the second site showed the removal of mercury (ppb) from a waste stream resulting in an effluent concentration of much less than 1 ppb. In another study, mercury (300-100ppb) from waste brine water containing high levels of calcium and salts the ICET media showed 8-10 mg/g capacities. In a simple small flow through filtration system a few grams of the ICET media reduced an influent concentration of 1000 ppb of mercury to 1 ppb, and disposable one time applications are possible. See Figures Below.

ICET is capable of supplying point-of-use systems as well as end-of-pipe treatment systems for heavy metal treatment.

The high capacities of the modified carbon surfaces toward cadmium, nickel, copper, lead, and zinc have been well established in various applied studies. ICET will gladly customize sorbents to your needs including specific metal sorbents, and a variety of media materials, inclubing fabric, films, granular forms, etc. We also offer process design and development consulting. Metals removing granular carbons are available in both trial and bulk quantities at half the price of ion-exchange resins.

It is noteworthy that even when a huge spike (300ppb) in mercury concentration occured, the ICET media was able to handle the challenge (figure 2).Figure 1: Site #1 Performance During Week 1, hourly samples

Red line, Influent Concentration; Blue line, Effluent Concentration; (ug/L). X axis indicates Hours. Y axis indicates Hg Conc.

Figure 2: Site #1 Performance During Weeks 2-7, daily samples

Red line, Influent Concentration; Blue line, Effluent Concentration; (ug/L). X axis indicates Days. Y axis indicates Hg Conc.

Figure 3: Site #2 Performance, Weeks 1-6

Red line, Influent Concentration; Blue line, Effluent Concentration; (ug/L). X axis indicates Run-Time in Days. Y axis indicates Hg Conc.

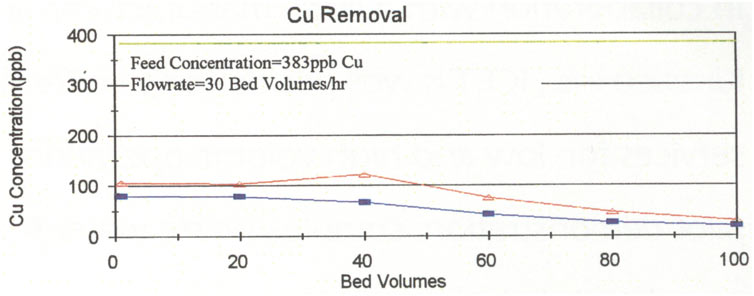

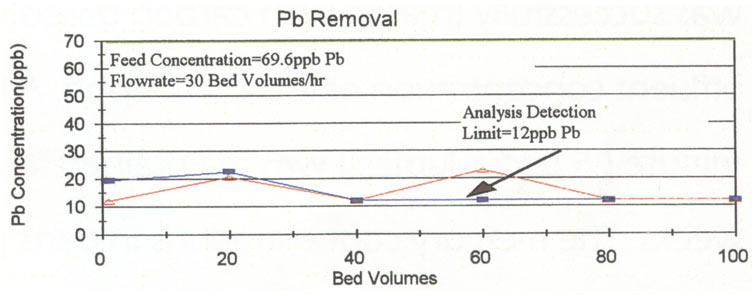

Removal of Lead and Copper is possible along with Mercury. In another study, mecury (30-100ppb) from waste brine water containing high levels of calcium and salts, the ICET media showed 8-10 mg/g capacities. In a simple small flow through filtration system a few grams of the ICET media reduced an influent concentration of 1000 ppB of mercury to1 ppb.

Figure 4: Copper Removal

Bench Scale Results. Bed volume on X axis. Cu conc. on Y axis.

Figure 5: Lead Removal

Bench Scale Results. Bed volume on X axis. Pb conc. on Y axis.

ICET will customize sorbents to your needs including specific metal sorbents, and a variety of media materials, including fabric, films, and granular forms. We also offer process design and development consulting.

For further information please contact shantha@icetinc.com